Hospitals Are Running Out of Face Shields. SMOA Can Help.

Face shields are necessary Personal Protective Equipment (PPE) when dealing with bodily fluids. Due to the increased strain on the healthcare system, many hospital and health care networks are suffering from a lack of face shields. However, the design of these face shields are uncomplex, and can be replicated using 3D printed models. Specifically, SMOA designed face shields to be used with Polyethylene Terephthalate Glycol (known as PETG or PET-G). Using PTEG allows for repeated sterilizations, extending the life of the product. SMOA will, of course, ensure that all products sent to hospitals are sterilized and approved by a doctor. SMOA's efforts symbolize the youthful flame of ambition, ingenuity and creativity.

SMOA Project Design Ideology

Phase I: Idea Conception

SMOA wanted to create 'something' to help medical professionals. While the psychological health is important, physical health is equally as important. SMOA researched and analyzed the crucial tools used by medical professionals duing the COVID 19 pandemic, and sought to make the most impactful product, while maintaining feasibility. PPE is now a scarce resource in hospitals, and health care workers are now forced to sacrifice proper health and safety guidelines to cope with "what they have". That simply is not okay, because doctors and medical professionals need to provide high-quality, safe care. Major PPE used by medical staff includes gloves, masks, a disposable gown, and a face shield. A face shield is the most easily accessible product for SMOA staff, since we can using Computer Aided Design (CAD) models to 3D print PTEG or PLA-based face shields. For the actual "shield" we will use divider-plastic, commonly used by students in binders.

Phase II: Prototyping, Iterations and Testing

|

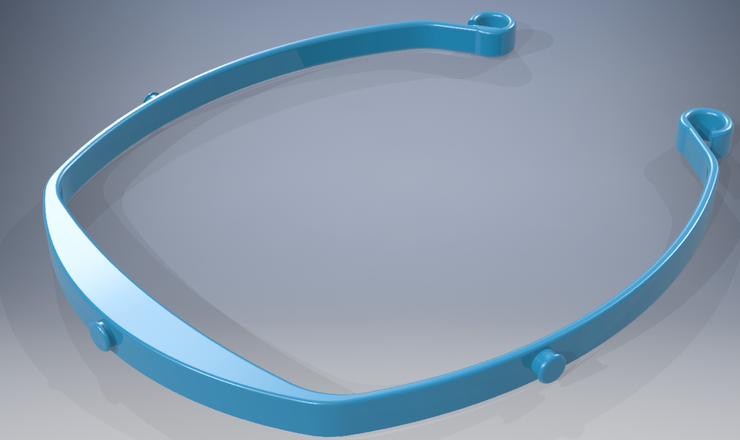

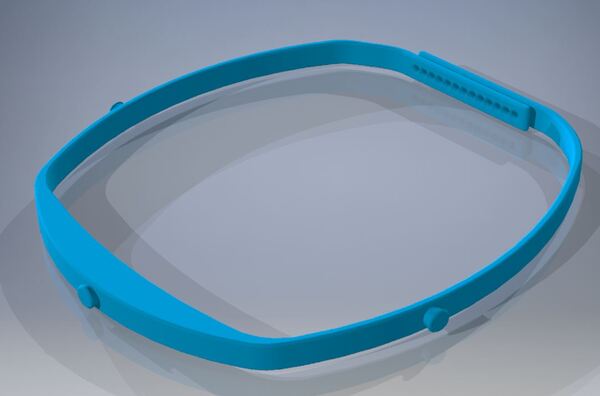

Based on designs available in the global maker community, SMOA combined sizing data, functionality constraints and printing material design choices to create the SMOA Face Shield Mk. 1, Mk. 2, and Mk.3. SMOA designed the Mk.2 to use a elastic band (like a hair tie or rubber band), to hold the band on the user's head. SMOA later discovered that the elastic band requirement presents a problem: elastic bands may not work with all of the band's sterilization methods. After collaborating with a doctor who is a leading COVID expert, SMOA designed a novel concept: a snap-on/off, adjustable face shield: Mk.3. The Mk.3 shield eliminates the need for an elastic band, and instead uses a clasp mechanism commonly found on baseball caps. The entire assembly is made from PTEG, and is approved for most sterilization procedures.

|